Selling to grocery stores changed our business focus to producing in volume. We started out by selling at farmers markets, but living in a college football town makes Saturdays a harder sell — if it was rainy and a football day, sales took a big hit. Weekday markets in our area were not cutting it, and florists were only taking certain crops, so we needed a way to sell the extra flowers through the week. Selling to grocers became the solution to all of those problems. The sale was already made when it was loaded onto the truck, no matter the weather, and the mixed bouquets could absorb whatever the florists didn’t buy that week (or I didn’t need for weddings). Now grocery sales are 38% of our business.

Below: At Sunny Meadows Flower Farm, a cart can hold 30 buckets of flowers. Loading the cart consistently helps the farmers keep track of quantity. Photos courtesy of Sunny Meadows. Our first grocery sale in 2008 was to a Whole Foods Market. We didn’t have a farmers market on a 4th of July weekend, so we went in there with some sunflowers, lilies, and a bouquet, which we left with our business card. We called later that week and learned that the floral manager was impressed with the quality and vase life of our flowers. The store already was buying from a lily grower, but the staff decided they had room for us with the sunflowers and bouquets.

Our first grocery sale in 2008 was to a Whole Foods Market. We didn’t have a farmers market on a 4th of July weekend, so we went in there with some sunflowers, lilies, and a bouquet, which we left with our business card. We called later that week and learned that the floral manager was impressed with the quality and vase life of our flowers. The store already was buying from a lily grower, but the staff decided they had room for us with the sunflowers and bouquets.

In order to sell to Whole Foods, we were required to get approved by corporate and be entered into their system before we could sell directly to the store. It took us about a month to get all the paperwork done and prepare ourselves for retail sales in the stores. There was a designer in the floral department who was our cheerleader and guided us through the whole process, which helped immensely. She let us know if we wanted to play with the big boys, we were going to have to suck up extra costs and requests, so we did. I will not say it was easy, but it was definitely worth the extra steps to get us started in grocery sales.

Below:To reduce the time they spent sticking both labels and UPC codes on sleeves, Gretel and Steve created labels for each type of product. The two rolls on the left have the UPC bar code printed on them for different price poinits. The roll on the right is for flowers sold at farmers markets. Whole Foods required our product to be sleeved and marked with a UPC. We purchased our UPCs online for about $10 each, although I think the price has decreased since then. Just be sure the website you are buying them from provides a certificate of authenticity with your purchase. We started by just printing the UPCs out on address labels, but some growers will purchase a UPC printer so you can use a pricing gun to label sleeves. Once you own the numbers, each store programs them into their system with a price and item description.

Whole Foods required our product to be sleeved and marked with a UPC. We purchased our UPCs online for about $10 each, although I think the price has decreased since then. Just be sure the website you are buying them from provides a certificate of authenticity with your purchase. We started by just printing the UPCs out on address labels, but some growers will purchase a UPC printer so you can use a pricing gun to label sleeves. Once you own the numbers, each store programs them into their system with a price and item description.

We decided that if we were going to have to put UPCs on them, we were also going to put our logo on the sleeve. We had stickers designed by PrintedTags.com, a company in Ohio that we still use. Since then, we have decided to get the UPCs printed directly on the logo sticker so we don’t have to sticker the sleeves twice. This cost a little more up front to design the separate stickers, but definitely decreased the amount of labor it takes to place stickers on sleeves. We still get a label with just our logo that we use at farmers markets. We decided to sticker and sleeve all market bouquets so people get the same experience they would when seeing our product in the grocery stores.

We buy our sleeves from A-Roo. We started with plastic, but now we use a Kraft paper sleeves for our bouquets. We went through a few different sizes, and have landed on a 14x14x4. Our seasonal bunches are still sleeved in plastic—medium for most products (14x16x4), but small for ranunculus and anemones (10x16x2). Making bouquets that fit properly in the sleeves is very important for grocery store sales. Know that the customer is going to see them from above the bucket, so you want a slight dome shape at the top of the bouquet for the flowers to really shine.

Invoices and payments

Invoices needed to be submitted upon delivery and look the same each time. Our first year, we created them in Microsoft Office, but after a computer crash and losing those records, we decided to go more legit with Quickbooks. Now we use Quickbooks Online so it is available on all our devices. Whole Foods requires two copies of the invoices to be signed upon receipt; one for the store and one for you to take home for your records. Each order comes with a Purchase Order number that has to be included on the invoice. We don’t save the paper copies once an invoice has been paid, but having the copy until then is useful in case of problems or missing payments.

Our payments from Whole Foods come Net 30, which means we don’t get paid until a month after our delivery. This is tough at the beginning of the season when you need the money, but it is nice in the fall when you are still getting paid a month after the flowers are gone. Other grocers may be Net 15, paying you two weeks later, or some will write a check at delivery,; it just depends on the store.

Below: Mixed bouquets change every month, from those featuring tulips and ranunculus in May through mixed annuals and perennials in summer, to marigolds and mums in October. Since our first year selling to Whole Foods, we have picked up other grocery stores in the area that we sell as Direct Store Delivery (DSD). Columbus seems to be a hot spot now for natural food grocery stores, which works in our favor. We now sell locally to three Whole Foods, four Giant Eagle Market Districts, and five other grocery stores from May to mid November. The chain stores usually require corporate approval, so it may be easier to approach a smaller, family-owned store to get started. It took us two years to get an appointment with the right person at Giant Eagle, but it was worth the wait.

Since our first year selling to Whole Foods, we have picked up other grocery stores in the area that we sell as Direct Store Delivery (DSD). Columbus seems to be a hot spot now for natural food grocery stores, which works in our favor. We now sell locally to three Whole Foods, four Giant Eagle Market Districts, and five other grocery stores from May to mid November. The chain stores usually require corporate approval, so it may be easier to approach a smaller, family-owned store to get started. It took us two years to get an appointment with the right person at Giant Eagle, but it was worth the wait.

We deliver to some stores once a week, but all the larger chains get deliveries twice a week. Our goal is to be able to sell from Mother’s Day through Thanksgiving, but this year we ended a week sooner than projected as we were running out  of flowers and wanted to save them for our Thanksgiving farmers markets. A couple of years ago, we tried to figure out how we could use Whole Foods to expand our business by using the distribution center like we know other growers do in different parts of the country. Our region’s Whole Foods rejected us since we were already set up for DSD, but luckily that made us look to other options, which led us to Heinen’s.

of flowers and wanted to save them for our Thanksgiving farmers markets. A couple of years ago, we tried to figure out how we could use Whole Foods to expand our business by using the distribution center like we know other growers do in different parts of the country. Our region’s Whole Foods rejected us since we were already set up for DSD, but luckily that made us look to other options, which led us to Heinen’s.

Heinen’s is a grocery store chain based out of Cleveland, Ohio, that consists of 19 stores in the Northern Ohio area. (They also have stores in Chicago, but we don’t box our product, so they don’t send it there yet.) Heinen’s distribution center has been a dream client. They take a truckload each week from July to mid October. It takes 2 ½ hours to get to Cleveland, so it is pretty much a full day of driving to deliver. Last year we hired a driver so Steve didn’t have to make that drive. Some growers  will hire a separate trucking or courier service if available in their area. Even though it is far away, it is worth it for the amount of flowers the distribution center can take and for how pleasant Heinen’s is to do business with.

will hire a separate trucking or courier service if available in their area. Even though it is far away, it is worth it for the amount of flowers the distribution center can take and for how pleasant Heinen’s is to do business with.

Planning and picking

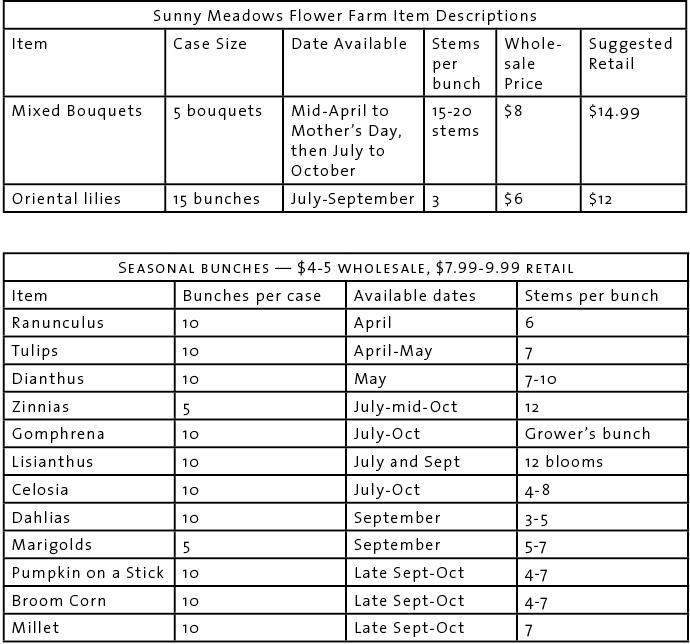

On Monday mornings, Steve and I walk through the fields to determine what we have available for the week’s orders. We get an idea of what’s blooming for florists, weddings, and grocers, and then relay the harvest plan for the day to the field crew. We email the buyer at Heinen’s with our projected availability for the week. We can fit a total of 100 buckets into our box truck, so we try to divide it out with about 65 buckets bouquets, 5 buckets of Oriental lilies, and the remaining buckets in seasonal bunches. This breakdown is usually 10-15 buckets of zinnias, 5-10 buckets of celosia, and then the rest filled in with whatever we feel we have enough of to bunch (lisianthus, gomphrena, tuberose, pumpkin on a stick, etc.). The seasonal bunches have a varying number of stems and the number of bunches per bucket also differs. We have a tall seasonal bunch UPC (10 per case), and a regular seasonal bunch UPC (5 per case). In the winter, the buyer sends out a survey to each store to assess how each item sold, and we work together to adjust our production. Since we have had success with this method, we plan to put together a survey for our other customers to figure out what it is they want, so we can adjust our planting schedules to fit their needs.

Heinen’s sends us an order with a PO by early Tuesday morning, and we typically bunch the Oriental lilies on Tuesday for their order. With practice, you will get better at estimating quantities when you look at the field. The more you get it right, the more confident you will become in your offerings estimated. Heinen’s does not require us to box our items, although some distribution centers do. Our Whole Foods requires boxes, and needs us to project availability two weeks out. They also have a more detailed tracking system with their Vendor Information Portal and Produce Traceability Initiative.

Sometimes since there is so much volume cranking through here, we have problems keeping count of the finished product buckets, so we have developed systems to help with that. Building a barn last spring definitely helped with flow, and we can use carts to roll the product in and out of the cooler and over to the loading dock. Our cart that holds the finished bouquet buckets holds 10 per shelf, 30 total. We count again as things are being loaded just to be sure we got everything. We don’t roll the carts onto the truck, but instead load the flowers into the box truck with shelves built into it, so we can fit three layers of bouquets high on the edges.

When approaching new customers, we recommend creating order guidelines and a projected availability. For our local grocers, the order deadlines are 7 a.m. Monday for Tuesday delivery, and 7 a.m. Wednesday for Friday delivery. Buyers would like a Monday delivery, but we couldn’t work that into our schedule unless Sunday was a full work day, and we were not willing to sacrifice the only day we might actually have off. We deliver to Heinen’s on Thursday, so everything is harvested and processed on Wednesday. This is why I need orders for Friday delivery from our local grocery stores by Wednesday morning. After Wednesday’s harvest I can pull any flowers I need for weddings, and then check to make sure we will still have enough flowers for all of our orders. Floral buyers seem to change each year, so at the beginning of the season, we will send order reminders to get the buyers used to the deadlines. We love grocery stores with standing orders each week, but for any grocers that have to create a PO number for each order, there is an extra step with them. We have had to be firm with Whole Foods in particular, so they have missed deliveries because of repeatedly late orders. On the previous page is a chart we send to potential customers or new buyers so they get an idea of all we have to offer. When you are working on pricing, know that most grocery stores are going to mark up 100%.

Takeaways from our experiences: 1. It doesn’t have to be Whole Foods; check in your area for family-owned or other natural food grocery stores. 2. Don’t be afraid to put yourself out there. You can grow it, now get out there and sell it! 3. If you want to play with the big dogs, act like a big dog. Have some order guidelines ready for them as well as a projected availability. 4. Don’t be afraid of getting sleeves, UPCs, stickers with your logo, or an official invoicing system. All of those incurred costs will pay for themselves and will help develop your brand. After you’ve started selling to these grocery stores, their customers will be asking for your flowers!

Next month: Gretel will write about planting enough flowers for a long season of supermarket sales, plus her system for making bouquets quickly.

Gretel Adams is the co-owner of Sunny Meadows Flower Farm in Columbus, Ohio. She contributes regularly to Growing for Market.

Have you ever lost precious seedlings in your greenhouse to frost? How about tossing a flat or two out due to heat stress or a missed watering? Or better still, stared at a tray of seeds that won’t germinate, with smoke coming out of your ears, because you’re sure someone (not you!) mis-watered them at a critical moment? Have you ever shrugged to yourself reading the growing instructions on a seed packet that says “Germinates best at 70 Fahrenheit” while standing in your 85-90 degree greenhouse? You’ve started to look into a germination chamber to solve some of these issues, but they look pricey and have limitations like not being able to handle as many flats as you’d like to start at once.

Have you ever lost precious seedlings in your greenhouse to frost? How about tossing a flat or two out due to heat stress or a missed watering? Or better still, stared at a tray of seeds that won’t germinate, with smoke coming out of your ears, because you’re sure someone (not you!) mis-watered them at a critical moment? Have you ever shrugged to yourself reading the growing instructions on a seed packet that says “Germinates best at 70 Fahrenheit” while standing in your 85-90 degree greenhouse? You’ve started to look into a germination chamber to solve some of these issues, but they look pricey and have limitations like not being able to handle as many flats as you’d like to start at once.