Increase efficiency, lower risk, and improve quality

Many small- and medium-sized farms are motivated to scale up, renovate, or improve their post-harvest areas and systems. Some want to make it easier to clean and strengthen their produce safety practices, others have outgrown their current set-up, and some are looking to create a more enjoyable workspace.

Washing is an effective way of removing field heat, hydrocooling the crop and getting it closer to storage temperature to preserve the shelf life of this salad mix. Photos by A. Chamberlin (UVM Extension) except where otherwise noted.

Washing is an effective way of removing field heat, hydrocooling the crop and getting it closer to storage temperature to preserve the shelf life of this salad mix. Photos by A. Chamberlin (UVM Extension) except where otherwise noted.

With summer upon us, heat is a major motivator — growers want to get the produce, and themselves, out of the heat and properly cooled as efficiently and effectively as possible. If you don’t beat that heat, every hour you delay cooling your produce can reduce its shelf life by a day or more, causing major headaches for you and your customers.

One way to reduce those headaches is to focus on your production flow: the steps you take and the tools you use to move your produce from the field, to the packhouse, into cold storage and out to the customer. Experience is the best teacher, and we’re going to share some advice, strategies, and farm-tested solutions from growers about what has worked for them. In the words of Silas Doyle-Burr from Last Resort Farm in Monkton, Vermont, where they’ve worked to continually improve: “How can we make this easier?”

To do this, growers have focused on improving their harvest and post-harvest practices by blending key principles of hygienic design and lean farming. This combination helps to lower produce safety risks and increase the quality of their produce — and life — on the farm.

Hygienic design is the process of intentionally creating or improving spaces and equipment using five main principles. (go.uvm.edu/hygienicdesign) The first is having visible and reachable surfaces. If you can’t see it and you can’t reach it, you can’t easily clean, sanitize or dry it. The second is to have smooth and cleanable surfaces that enable efficient and complete cleaning and drying. A dirty and damp surface, instead of clean and dry, ends up creating more mess and more stress.

Cleaning tools and supplies are easily accessible hung via magnets or hooks on a metal wall.

Cleaning tools and supplies are easily accessible hung via magnets or hooks on a metal wall.

The third is to have no collection points on equipment, like niches or sandwich joints, that accumulate water, food, and other materials that feed bugs like ants and roaches or provide prime growing areas for plant and human pathogens. The fourth is to use materials compatible with the product being handled and the cleaning, sanitizing, and drying processes you use. This means your tools, from brushes to detergents to buckets, should match the job.

Last, but not least, the practices, systems and buildings you use should protect the product from contamination. Your flow and design should ensure produce coming in from the field doesn’t cross paths with produce heading out to the customer, leading to cross contamination. Birds and rodents should not view spaces on your farm as perfect places to eat, breed and poop. A complicated or clumsy system or dirty building will lead to dirty produce and long, inefficient days, which lead to long, inefficient seasons. Farming can be hard and these principles ease that strain.

Ben Hartman, author of The Lean Farm, has a great description of a farmer who uses lean farming systems. “The lean farmer plugs into the community, listens to what food is needed, and then grows exactly what customers want, in the right amount, at the right time. No effort is wasted. Rather than keep every tool, the lean farmer selects just a few to get the work accomplished.” And, maybe most importantly, “… the lean farmer earns a sustainable wage through efficient production and a focus on high-value crops.”

Silas Doyle-Burr of Last Resort Farm in Monkton, VT, renovated his family’s old dairy barn into a vegetable wash/pack building with 5 different coolers to optimize storage conditions for his CSA and farmers markets.

Silas Doyle-Burr of Last Resort Farm in Monkton, VT, renovated his family’s old dairy barn into a vegetable wash/pack building with 5 different coolers to optimize storage conditions for his CSA and farmers markets.

Putting a little spin on that, we can say that the lean farmer plugs into the farm, listens to what the farm needs, and puts the right systems in place to do the right practices at the right time. This includes clear locations for key tools and equipment, built-in efficiency with good layout, easing movement with wheels or other conveyance, and keeping paperwork that improves practices.

With flow and those definitions in mind, this article will move through the farm: Field - Wash/Pack - Cold Storage.

Field

Our first step is a place to stop and plan for reduction of field heat all along the post-harvest chain. There is a tendency to rush in the fields, get it out, quick and dirty, and sort out any problems in the wash/pack. Of course, we want to be quick with harvest. But, we also want to be smart. Scheduling harvest when field heat is low and using shade to get harvested crops out of the sun quickly can reduce the need for pre-cooling and protect quality down the line.

When harvesting, you can simply use shade to promote cooling or to avoid gaining heat on the side of the field or in the back of the truck. Pre-cooling is another way of reducing produce temperature more quickly than just setting it in a cooler. Simple, small-scale forced-air cooling systems can be assembled inexpensively. (http://go.uvm.edu/forcedaircooling)

These steps protect the quality you have achieved in the field at the time of harvest because quality isn’t going to improve in post-harvest handling, storage and distribution. Remember, post-harvest is more like a hotel than a hospital.

Julia Asherman at Rag & Frass Farm in Jeffersonville, Georgia, shares that she and her crew “do quality control at every stage, especially as we harvest. We are not grading in the pack shed but instead we are grading in the field as we work. We don’t want to spend time washing or moving plant material that is not intended for sale, so with a few exceptions (like green onions) we are bunching, manicuring, or separating culls in the field. This means once we are out of the field it is really simple in the packing shed to get it washed, packed, counted and into cold storage.”

Often overlooked, the bins, buckets, baskets and totes (go.uvm.edu/bins) you use for harvesting play a special role on your farm. Many people use many different things, including 5-gallon pails, milk crates, muck buckets, totes found at the box stores and blue flip-top totes. Does it matter what you use? Not really, as long as you have a method to your madness that minimizes contamination and reduces mix-ups and wasted time.

Hand trucks are a useful tool for moving stacks of crates around the wash/pack, cooler or delivery van. Dollies under the crates themselves are also a back-saving investment. The forced air cooler below was sized to precool up to half a pallet of bins when placed inside a walk-in cooler. A blower (not visible, on the far side of the vertical plenum) is used to pull cold air through the pallets. Care should be taken to prevent the plastic from touching the slab. Re-usable materials can be used to cover the pallet as long as they can be sanitized.

Hand trucks are a useful tool for moving stacks of crates around the wash/pack, cooler or delivery van. Dollies under the crates themselves are also a back-saving investment. The forced air cooler below was sized to precool up to half a pallet of bins when placed inside a walk-in cooler. A blower (not visible, on the far side of the vertical plenum) is used to pull cold air through the pallets. Care should be taken to prevent the plastic from touching the slab. Re-usable materials can be used to cover the pallet as long as they can be sanitized.

Either the containers work well and you love them or you learn — over and over again — how frustrating they can be as you try to make mismatched containers fit specific jobs. Purchasing harvest tools that are easy to clean, sanitize, and use is a key place to save time and keep your quality high. Sometimes the money saved inheriting someone else’s broken bins goes down the drain as you spend tons of time trying to get them clean and in good working order.

Wash/pack

Instead of scattering harvest containers around the wash/pack area, find ones that can be stacked, nested and are easy to pick up. Stacking supports more efficient use in a cooler, on a hand truck, or in your delivery vehicle, and nesting saves space when storing them empty. A lot of growers use different colored bins for different tasks, making it easier to know which are field totes or storage totes, and they keep cull (compost) and harvest buckets separate to ensure clean produce. Color-coding also helps keep the harvest bin brushes and bathroom brushes separate. You don’t want to get these mixed up. It happens, it’s gross.

Ventilated bins can serve as simple, cleanable spray tables.

Ventilated bins can serve as simple, cleanable spray tables.

Before you spray, rinse, dunk, or wash anything, ask yourself why. Does this crop really need to get wet? Washing can be important for aesthetics and getting some grit out, but it may not be as necessary as you think as it gobbles up tons of time and labor. Demetrius Milling, from Love is Love Farm in Decatur, Georgia, shares that with a few exceptions, for “cucumbers, tomatoes, peppers — we don’t wash them.” For most of their other crops, they “save time by harvesting in the morning and just spraying off, not dunking. Once you dunk it, it’s more labor. We decided the best option for us is to spray it and get it in the cooler as quickly as possible.”

Bunched scallions being washed in a triple bay sink.

Bunched scallions being washed in a triple bay sink.

For crops you want to spray off, like a mess of root crops with a high soil load, a spray table is going to make a world of difference. (go.uvm.edu/spraytables) Applying the principles of hygienic design to a spray table leads us to think about the clean-ability, assembly, and durability of the materials used to build the table. Wood and galvanized metal may be appealing and easily accessible, but are not very easy to clean completely and will wear down over time with repeated soaking and drying cycles.

Repurposed three-bay restaurant sinks are often made from stainless steel and provide a sanitary option for triple rinsed greens. A section of wire shelving, when placed on top of the sink makes a simple spray table with a built in drain.

Repurposed three-bay restaurant sinks are often made from stainless steel and provide a sanitary option for triple rinsed greens. A section of wire shelving, when placed on top of the sink makes a simple spray table with a built in drain.

The water you use on your spray table can take some of the field heat out of crops. Placing your spray table outside of your wash/pack area helps keep the inside cleaner and drier. As you spray, look down at your feet. Are you creating puddles?

Work to create a mud free, or low mud, and comfortable work area by planning for collection of the water with a pan and having intentional drainage away from the work area. Reducing the mud you’re tracking around also cuts down on slipping and sliding, keeps cooler floors cleaner, and improves the happiness of your feet on a cold day.

How people, product, water, and waste flow through your wash/pack has a major impact on the amount and quality of time you spend there. Ideally, the flow moves in one direction from the field to the cooler or market. This helps avoid backtracking (wasted steps) and potential cross contamination (mentioned earlier, we want to avoid clean produce interacting with dirty produce coming in from the field).

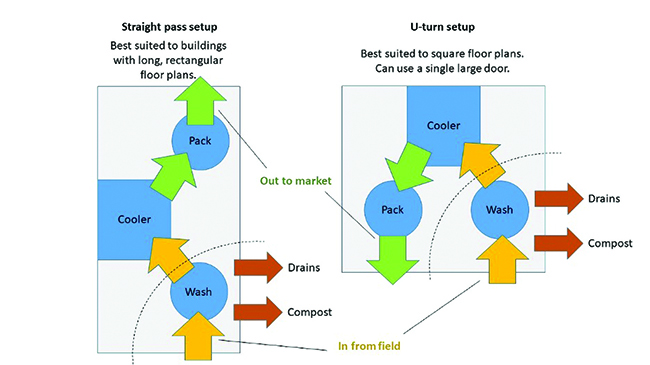

The two schematic layouts shown provide very generic samples of wash/pack flow arrangements and the graph paper diagram shows a farm developing plans for their future wash pack, with moveable pieces of paper as they play around with placement and design. Whatever design works for your farm, the principles remain: save steps, prevent cross-contamination and get the product to storage temperature as quickly as possible.

Two common flow arrangements for wash/pack layouts. The key point is to ensure intentional flow that minimizes the time it takes to get produce to storage temperature in the cooler and also minimizes the risk of cross-contamination. Figure: C. Callahan (UVM Extension).

Diagramming your wash/pack area, you’ll see that where you wash your produce often takes up a lot of space. (go.uvm.edu/sinks) Stainless restaurant sinks — large, durable, easy to clean, and fairly easy to find used — remain a popular option. If you don’t have fancy restaurant sinks, that’s okay. You don’t need them to be efficient and regulations like the Produce Safety Rule do not require fully stainless steel equipment, just that tools and equipment are of “adequate design, construction, and workmanship to enable them to be adequately cleaned and properly maintained.”

Hygienic design of produce equipment means that it’s constructed with cleanable materials like stainless steel and durable plastics.

Hygienic design of produce equipment means that it’s constructed with cleanable materials like stainless steel and durable plastics.

If what you have now is working great for your needs, and it meets this requirement, then keep using it. If you are ready for an upgrade, but not in a place to upgrade to stainless steel, there are quite a few other options that might make your produce washing flow more smoothly, reducing the amount of time it takes to get into the cooler or out to market.

Planning for hose management with hangers or reels is a good way to make sure water is ready when you need it and that the hoses stay off the ground when not in use.

Planning for hose management with hangers or reels is a good way to make sure water is ready when you need it and that the hoses stay off the ground when not in use.

Stock tanks or food grade plastic barrels are nice options and their height is easily adjusted by using wood or cinder blocks. Once you find a height you like, a metal stand can be a good addition with a bonus that it’s possible to move around with a pallet jack. Sink height may not seem like a big deal, but after a whole season standing there, you’ll be glad you adjusted the legs to bring them to a comfortable working height. Better to be smiling at the market than grimacing from back pain. Another way to experiment with height is to use long and adjustable water supply lines and hoses. You can dive deeper at go.uvm.edu/hoses to brainstorm different ways to have water when and where you need it.

Cleaning and sanitizing (http://go.uvm.edu/clean-sanitize-disinfect), mentioned a few times now, is important to get right to protect your health, time, and bank account. Traditionally, this is taught as a four-step process, but we’d like to add in Step Zero and Step Five.

Step Zero: Visually inspect. Look and see if it needs to be cleaned or sanitized. Just like all produce doesn’t always need a washing step, not every bin always needs a cleaning step. Think about adding a visual inspection step in your standard operating procedures: “Is this surface visibly dirty?” If not, you may instead rely on a master cleaning schedule to come back to it based on time.

Step One: Remove Dirt and Debris. Brush or otherwise remove the bulk of the dirt and debris from the surface.

Step Two: Clean with a Detergent. This step involves a detergent, generally water, and scrubbing. This is where elbow grease matters. Scrub the whole surface, paying special attention to the places that obviously need more time based on what you see. Be sure you are using a cleaning tool that is specific to the purpose and can be cleaned and dried.

Step Three: Rinse with Water. Rinse with clean water that has no detectable generic E. coli.

Step Four: Sanitize. The final step in cleaning and sanitizing involves correctly applying an antimicrobial solution (sometimes called a sanitizer) to lower the number of germs on the surface to a safe level. Read and understand the label on the sanitizer to be sure you are using it correctly (go.uvm.edu/clean-sanitize-disinfect).

Step 5: Intentional drying. This can be air drying, which is usually most efficient and effective. Providing time for the surface to dry ensures that any moisture that might support pathogen growth and reproduction is minimized.

Cold Storage

Establishing and maintaining a cold chain, and getting your produce to the appropriate storage temperature quickly, helps maintain peak harvest quality. Avid readers of this magazine will know from past issues that CoolBots are not for everybody, but we encourage you to think about your scale and look into them or other means of refrigeration.

A CoolBot installed in a small walk-in cooler with walls finished with galvalume roofing panels and a ceiling finished with Trusscore PVC panels. Note the lighting which helps make sure everything is easy to see.

A CoolBot installed in a small walk-in cooler with walls finished with galvalume roofing panels and a ceiling finished with Trusscore PVC panels. Note the lighting which helps make sure everything is easy to see.

If you do go the CoolBot route, or are looking to up your CoolBot game, growers have given us this advice. Put your money into good insulation. Plan for maintenance like cleaning the air conditioner coil and clearing the drain pan and drain hole. Place your cooler in the right location, preferably in the shade and protected from elements. We’ve seen a lot of coolers roasting in full sunlight. Pitch the AC unit slightly down toward the outside to ensure water can flow out of the drain pan and not down your cooler wall and potentially onto your produce.

Selecting the right bin for the job, having different bins for different jobs, and having space to store them is critical. In this case, at Root 5 Farm in Fairlee, VT, Danielle uses plastic pallets to keep them clean, upside down, and off the slab to prevent cross-contamination.

Selecting the right bin for the job, having different bins for different jobs, and having space to store them is critical. In this case, at Root 5 Farm in Fairlee, VT, Danielle uses plastic pallets to keep them clean, upside down, and off the slab to prevent cross-contamination.

We could fill countless pages about this. And we’ve captured more stories on the University of Vermont Post Harvest Case Studies page (go.uvm.edu/phcs). Know a resource you need? Have thoughts on improving existing resources? Want to know when new resources are released? Stay in touch and be involved using our website, go.uvm.edu/scrub for Sanitizing and Cleaning Resources for yoUr Business [SCRUB]. SCRUB will rely heavily on peer-to-peer learning using written and visual case studies, grower-led workshops, and feedback from growers like you.

This rack keeps clean bins clean and provides both a home for them to be stored and a place for them to dry after cleaning.

This rack keeps clean bins clean and provides both a home for them to be stored and a place for them to dry after cleaning.

Chris Callahan, Agricultural Engineer, and Andy Chamberlin, Agricultural Engineering Technician, with University of Vermont Extension, and Billy Mitchell, FSMA Training Coordinator, with National Farmers Union, work with the Sanitizing and Cleaning Resources for yoUr Business (SCRUB) project funded by the USDA Food Safety Outreach Program. For more practical produce safety information visit go.uvm.edu/scrub or follow on Instagram at @uvmextageng and @nationalfarmersunion.