This article originally appeared in the August 2016 issue of Growing for Market Magazine.

Consider a perennial crop that is more shelf-stable than most fruits, quicker to produce than most nuts, and in such demand that U.S imports far exceed domestic production while consumption continues to rise. In June I attended the annual meeting of the Chestnut Growers of America (CGA), co-hosted by the University of Missouri Center for Agroforestry (UMCA), where an experienced grower told me, “This is one of the few industries where you want more competition. We need that critical mass. We’ll give [new growers] all the support they need.”

Chestnuts offer two potential avenues for market farmers: a small-scale source of side income as a specialty market/CSA product, or a larger-scale investment in a new perennial crop with a bright future. We’ve been interested in chestnuts for several years now, and hope to inspire some GFM readers to take a closer look at this unique and interesting crop.

Chestnuts: the food

Just what are chestnut growers marketing to their customers? Consumer-oriented publications from UMCA describe chestnuts as being nutritionally similar to whole grains, with less fat than pecans and walnuts, and fewer calories than peanuts and cashews. They contain about the same vitamin C as an equal weight of lemons, and are high in complex carbohydrates. We can personally vouch for their sweet, addictive flavor and versatility in the kitchen. Plenty tasty eaten on their own, chestnuts also come with a variety of potential value-added possibilities, including chestnut flour (gluten-free!), dried chestnuts, sweet purees, and even alcoholic beverages. As a fall-harvested, moderately shelf-stable product with a strong cultural connection to the winter holidays, locally grown chestnuts have a lot of marketing potential with customers, chefs, and other outlets.

Below, a mature chestnut orchard at HARC in early June. Note the grid of light on the ground that indicates well-spaced trees receiving sun on all sides. All photos by Eric Reuter.

History of production

The chestnut tree (genus Castanea) has developed into at least seven distinct species, including one in Europe, one in Japan, three or more in China, and two or more in North America. Despite their names, horse chestnuts, water chestnuts, and chestnut oaks are not related to Castanea. Human cultivation started in Bronze Age Turkey, beginning a long tradition of chestnut cultivation in the Old World. The Romans spread chestnuts throughout their empire, and Asian cultures have grown them for many thousands of years. By contrast, North American chestnuts were never domesticated in the same way, developing into massive, long-lived wild trees that were estimated to compose least 25% of Appalachian forests. Semi-wild groves may well have been managed and encouraged by Native Americans, who valued the rich annual production of wild nuts, more reliable than oaks or other nut-producing trees. European settlers in eastern North America regarded it as the “perfect tree” for its combination of food production and quality timber.

However, the isolated evolution of North American chestnut species proved their undoing when an Asian pathogenic fungus (Cryphonectria parasitica, or chestnut blight) arrived in the early 20th century. Old World chestnut species had developed varying levels of resistance to the blight, but it devastated American chestnuts, wiping out an estimated 4 billion trees and essentially removing chestnuts from the landscape within the span of a human lifetime. Today, American chestnut species still cannot be grown reliably without succumbing to the blight, though various breeding programs have long tried to develop resistant strains. However, Chinese species are highly resistant to blight (European and Japanese species moderately so) and have become the basis of a new North American chestnut industry that has plenty of room to grow.

Growing chestnuts

It’s possible to raise chestnuts throughout much of the United States, well beyond the Appalachian-centered range of the native American species. CGA’s website lists member growers in 23 states, while the Agricultural Marketing Resource Center at Iowa State University lists the highest acreages planted as being in Michigan, Florida, California, Oregon, Virginia, and Iowa.

Soil and location matter; chestnuts need well-drained soils and hate wet feet. At a tour of UMCA’s Horticulture and Agroforestry Research Center (HARC), we walked several acres of mature chestnut trees planted on a hillside of deep, rich loess soil nearly perfect for chestnut cultivation. The only gap in the orchard sat in a gentle swale where water collected, encouraging Phytophthora root rot that had killed trees planted there. On the other hand, irrigation may be necessary in late summer and fall to ensure proper nut development, depending on climate. Chinese chestnuts are cold-hardy down to around -20ºF; UMCA suggests choosing planting locations as you would for peaches, allowing for good air movement and avoiding frost pockets. Practicality of fencing to exclude deer is another consideration in determining a good site. Chestnut trees should be planted initially at about 40-50 trees per acre, on a grid spacing of roughly 30 feet between trees, allowing enough space for sunlight to reach all sides of the mature trees. Commercially viable yields should begin between years 6–9, with trees beginning to reach mature production between years 12–15, and lasting for 30 or more subsequent years before beginning to decline.

Opinions on the right cultivar to plant vary widely, with experienced sources largely advocating for grafted trees, but with some opinions making a case for seedlings from a good breeding program. Either way, blight resistance is essential, and thus the best choices for planting stock include Chinese varietals or hybrids of European/Japanese/Chinese origin. Chestnuts are primarily wind-pollinated and require cross-pollination between cultivars. Suggestions for cultivars also change regularly due to active breeding programs producing new results and ongoing collection of data from existing varieties as they mature. For example, a 2012 UMCA publication states, “The ‘Peach’ cultivar, although producing consistently large sized nuts, is no longer recommended for the commercial grower as a result of consistently low yields.” However, at the 2016 CGA meeting, UMCA released new data showing the annual yields from “Peach” skyrocketing from 13.6 lb/tree in 2011 (11-year-old trees) to 70.4 lb/tree in 2015, a trend seen in several other previously underperforming varieties as well. It’s strongly recommended to seek the advice of other growers, breeders, or researchers in your region before choosing varieties.

Managing and harvesting

Chestnut trees are considered relatively problem-free once established; Susan Freinkel notes in her 2007 book American Chestnut that “some nineteenth-century critics complained that raising chestnuts induced peasants to laziness,” though the modern spread of new diseases and pests changes that equation somewhat. The trees need proper pruning in early life and typical maintenance concerns such as mowing and fertilization. Most problems relate to nut production and quality; a lengthy discussion at the CGA meeting centered on the spread of blossom end rot. It is caused by a fungus in chestnuts, which results in damaged nuts with a reported 7%-30% loss on the grading line. Interestingly, another pest, chestnut gall wasp, is partially controlled by the blossom end rot fungus. Growers reported that fungicide applications provided no benefit, and that the problem was mainly confined to mature orchards with lots of dead wood.

Chestnuts form within spiny burs, which open and drop the nuts from the tree when mature. Working with and around these burs is the largest challenge in chestnut harvest. Manual harvest is best done with a tool like the Nut Wizard, a rolling basket used for collecting items such as fruits, nuts, and golf balls. Some burs may have to be cracked by gloved hands or heels to release their nuts. Mechanical harvesters use various combinations of sweeps and vacuum suction to collect everything and sort the nuts from the burs. These harvesters can work up to ten times as fast as manual methods, according to discussions at the CGA meeting, but carry their own burdens of cost and maintenance. Starting at around $16,000 for the simplest versions, these are suited to large-acreage orchards or cooperatives of nearby growers.

Below, catkins and burrs forming on a chestnut tree in early June.

Chestnuts should be harvested as soon as possible after they drop, preferably every day or two, to maximize quality and minimize loss to wildlife. Ideally, the orchard will be mowed close the ground and all debris removed before nuts begin to drop. Production can cover several weeks, generally in September or October depending on location. Because chestnuts are lower in oil and higher in water than other nuts, they are not as shelf-stable, and must be held near 32ºF until sale or use, making them more like a fruit than a nut in this regard. Chestnuts will not store year-round unless further processed (by drying or freezing, for example), making them a seasonal product for fall and early winter. Fortunately, that’s precisely when culinary culture suddenly wants holiday chestnuts.

Chestnuts are covered by the Food Safety Modernization Act Produce Rule; surprisingly, the FDA chose not to exempt them via the “rarely eaten raw” list. There is some uncertainty about the precise implications of this. Generally, FSMA prohibits harvest of “drops”, though it gives exceptions such as root vegetables (thankfully) and “produce that is intentionally dropped to the ground as part of harvesting (such as almonds).” This exemption is expected to extend to chestnuts, even though almonds tend to be actively shaken and chestnuts are allowed to passively drop. (Shaking chestnut trees is not recommended, as this will dislodge unripe nuts, from which burs have not loosened.) FSMA rules may have other implications on chestnut management, including rules about proper wash water and storage conditions. Pasturing domestic livestock or poultry in the orchard may also be frowned upon, a restriction already faced by organic growers, who ironically would especially benefit from natural fertility inputs along with pest and grass control provided by animals. Aside from this particular limitation, organic production of chestnuts is a viable option, with organic chestnuts commanding higher prices than conventional.

When adding chestnuts to a diversified market farm, the extra labor requirements for harvest during a busy time of year are a potential downside. However, many market farms can capitalize on existing walk-in cooler infrastructure to store a crop of moderate size, as well as existing networks of customers and marketing channels to make chestnuts a crop worthy of consideration. Another model for finding labor comes from Redfern Farm in Iowa, which uses a U-pick model. Owners Tom Wahl and Kathy Dice told me:

“Last year, of our 4600 pounds total harvest, the customers harvested 4300. By the end of last season, our waiting list had grown to 126. Groups come mostly from Waterloo, Iowa, but also from Des Moines, Chicago, St. Louis, Kansas City, Omaha, Sioux City, Iowa, Fargo, North Dakota, and Minneapolis.

“We start calling names on the list, give them a range of possible days, and they pick one from that. When they show up (with anywhere from one to five vehicles) I take them over and show them where the trees are, and how to use the Nut Wizard harvesting tools if they are new customers. They usually pick until all the nuts are gone, then come back to the farmstead to weigh them out. I weigh and bag the nuts, and charge them 50 cents per pound less than what I would have charged if we had harvested them. We explain to people who are just getting on the list that it may be years before they get a call from us because we only have so many trees and there are so many people ahead of them on the list. I have been calling some other nearby growers, and some of them have been experimenting with PYO--and I think they have been very pleased with the results.”

Economics of production

Are you thinking of transitioning annual fields to perennials, perhaps as part of a move towards retirement? Do you have a spare acre or two of suitable land? Do you want just enough trees to supplement a CSA or market stand? Or do you want to dive into chestnuts at a large scale? Establishment costs, harvest labor, and potential markets are important economic considerations in determining the appropriate scale.

UMCA suggests that orchards up to 5 acres (~250 trees) can be managed with manual methods, though other discussions at the CGA conference suggest that 1-2 acres may be a more reasonable limitation depending on your situation. One standout in this regard is Chestnut Charlie’s, a 20-acre certified organic orchard in eastern Kansas that doesn’t use mechanical harvesters, though they do hire harvest help.

A 2015 UMCA publication estimates the 3-year establishment cost of a 1-acre, 50 tree chestnut orchard at just over $3,000 for supplies (plus optional $2,000 for deer fencing). For comparison, a Michigan State University (MSU) analysis tool estimates a total 5-year establishment cost (with fencing) at around $8,000, although this calculation includes some significant costs that may not relate to all situations, such as well-drilling ($1,100) and land opportunity cost ($1,000). Neither estimate included all labor costs or the significant revenue potential for alley-cropping or perennial polyculture during the orchard’s establishment period.

So what can you expect from this investment? Mature yields, on quality sites with proper management, generally achieved within 15 years, can range from 2,000 lb/acre to over 3,500 lb/acre. Wholesale prices average $2-$3, up to $7 retail. Thus a mature orchard could gross anywhere between $4,000/acre to $24,500/acre annually, certainly lower than the equivalent area of intensive vegetable production but with an accompanying lower cost of management and production. Net income is harder to estimate, with labor likely to be the highest input cost, particularly during the already-busy fall harvest season. See Table 1 for a general estimate of chestnut production and value for various orchard sizes. Even at the low-end estimates for a single-acre orchard, a 100-member CSA could provide each share with 5 lb of chestnuts and still sell ¾ of the annual production at market. Alternatively, a small ten-tree planting could provide that same CSA with 5 lb of chestnuts for all its members.

If you’re interested in getting into chestnuts at a larger scale, there’s room in the market. According to a recent producer survey by UMCA, 45% of respondents were growing 5 acres or less. Orchards much above a few acres probably should invest in mechanical harvesters, which save large amounts of labor in collecting, processing, and bagging tens of thousands of pounds of nuts. There will also be additional costs for management and storage, but larger-scale growers I talked to felt that the chestnut business was profitable and growing.

Chestnuts in the crop mix

Regardless of scale, chestnuts fit well into the diverse perennial polyculture systems advocated by Mark Shepard and others. During the first 10 years, a variety of alley crops can be grown between the widely spaced rows of young saplings. As the trees mature, closing in canopy space and ramping up production, the orchard floor can either be cleared and mowed for easiest harvest, or transitioned to more shade-tolerant crops like brambles. Chestnuts are also well suited to silvopasture, allowing livestock and poultry to keep the grass down, fertilize the trees, and clean up the orchard (though organic rules can restrict this practice). All of these approaches supplement the base income of the chestnut orchard but aren’t usually included in basic economic estimates.

One young farmer I met at the CGA meeting is enthusiastic about chestnuts’ potential. John Lee recently moved to Kansas to start Wakarusa Valley Permaculture, where he hopes to integrate perennial polyculture with pastured meat production. “I had no idea how few US chestnut growers there are,” he told me. “That helps in deciding to include chestnuts on our farm. Other than selling whole or processed nuts edible for human consumption, we plan to process any unsold nut yields through finished hogs to be sold as premium-flavored meats.”

The role of co-ops

Co-ops are becoming increasingly important in supporting the developing US chestnut industry; there are producer co-ops in Iowa, Michigan, Ohio, and Florida. Producer surveys by UMCA in 2012 and 2016 showed a 10% increase in growers marketing through co-ops. The co-op system allows growers small and large to pool their production and reach larger markets, while also potentially pooling equipment and knowledge. A group of growers who can share mechanical harvest equipment certainly has an economic advantage over individual orchards.

I asked David English, who manages over 2,500 trees on 27 acres in Florida and was just elected the new president of the CGA, for his perspective on chestnut co-ops. “I do agree that for smaller growers, not really in it for the money, or just getting established, a co-op is the best way to go,” he told me. “Equipment sharing is really important, especially for what’s needed to properly process and store. Networking within the co-op group can help new growers learn from other’s mistakes, I mean experience. Co-ops are typically best with bulk sales and less labor costs when everyone pitches in to process and store, but someone still has to go out and beat the bushes to sell the nuts. That’s the tough part. You have the cost of the bags, the site where it is all done, the building it is all housed in, the cooler; all these expenses are paid back to the co-op through sales.”

Even for CSA/market farms planning only a small planting there could be significant benefits to working together among several growers to plan coordinated chestnut production, particularly if different members bring different strengths to the table. For example, perhaps one farm has a perfect planting site but another farm has better facilities for handling and storing the harvest and their labor could be pooled to better manage the workload.

How to proceed

If anything is certain about growing chestnuts, it’s that you don’t have to go it alone. Every grower I talked to was excited about their crop’s future and the potential to help more farmers get started. Chestnuts inspire a passion among those who get involved, whether the life-long breeders working to revive a decimated wild species or the commercial growers seeking to replace the $12 million of annual imports with domestic production. Even a CSA farm with ten trees can introduce a hundred or more households to this tasty, healthy, food, and help build customer demand for this perennial palate pleaser.

Resources

Chestnut Growers of America: http://www.chestnutgrowers.org/

University of Missouri Center for Agroforestry: http://www.centerforagroforestry.org/pubs/chestnut.pdf

Michigan State University Extension: http://msue.anr.msu.edu/topic/info/chestnuts

American Chestnut, 2007, Susan Freinkel, University of California Press.

Eric and Joanna Reuter have been integrating food and farming into the ecosystem at Chert Hollow Farm in central Missouri since 2007. Visit their website at www.cherthollowfarm.com.

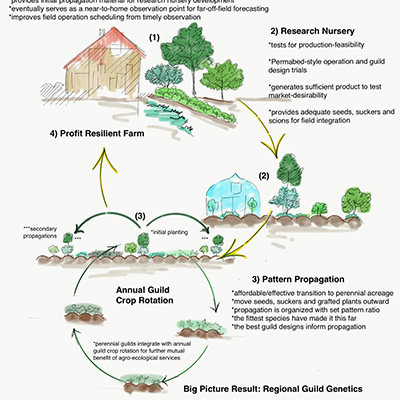

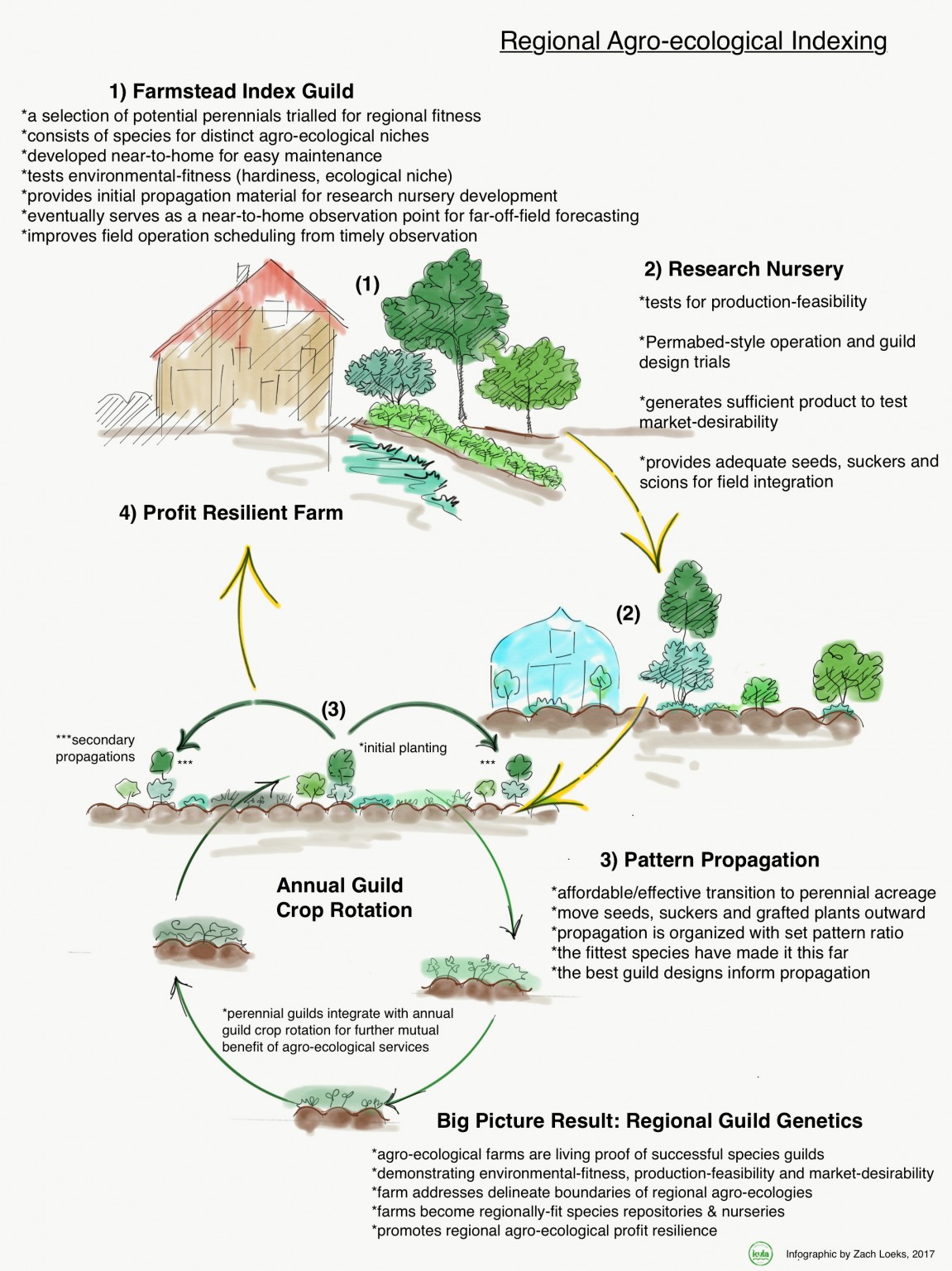

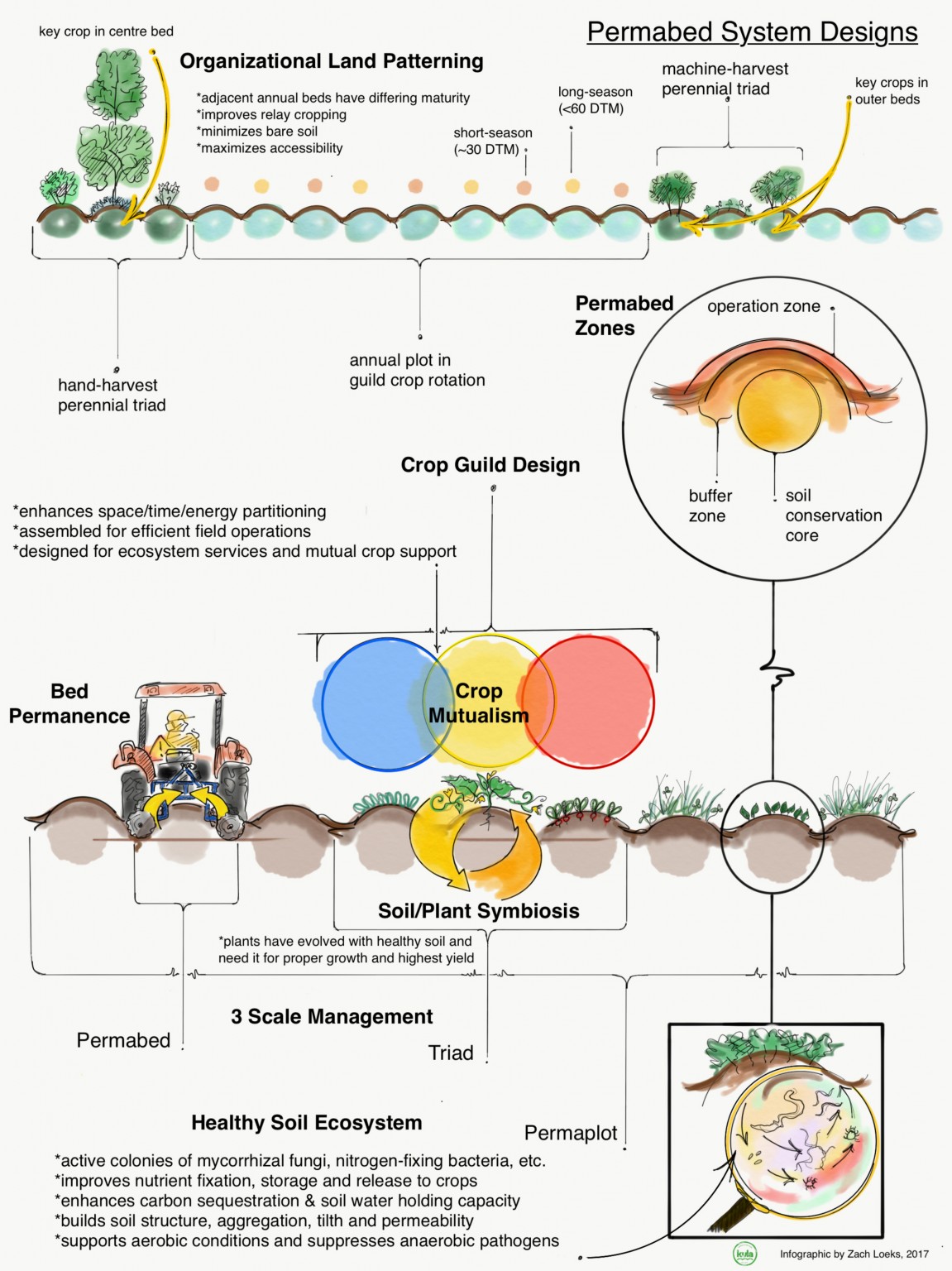

This is the first of a two-part article about using permaculture techniques to improve the profitability and resiliency of market gardens.

This is the first of a two-part article about using permaculture techniques to improve the profitability and resiliency of market gardens.

Diversify your boxes and bouquets with apples and branches

Diversify your boxes and bouquets with apples and branches

work The Holistic Orchard is such a book. The author, a longtime fruit grower, shares a vast store of experience about growing tree fruits and berries

work The Holistic Orchard is such a book. The author, a longtime fruit grower, shares a vast store of experience about growing tree fruits and berries

Floral designers get creative when it comes to vases and vessels. For Emily Calhoun at Floriography in New Mexico that means sometimes arranging flowers and desert plants in desiccated horned cow skulls. The floral cow skull is a signature of Floriography weddings.

Floral designers get creative when it comes to vases and vessels. For Emily Calhoun at Floriography in New Mexico that means sometimes arranging flowers and desert plants in desiccated horned cow skulls. The floral cow skull is a signature of Floriography weddings.

Sisters grow native perennials in Florida and New York

Sisters grow native perennials in Florida and New York

Since its founding in 1968 by my husband Eliot Coleman, Four Season Farm has sought to produce the best vegetables possible, using soil-based organic methods, on a small amount of land. When I showed up in 1991, Eliot had begun to pioneer winter vegetable production, and I was delighted to give up the landscape design business I’d run in Connecticut and grow veggies with him. Then, about 10 years ago, flowers started to creep in.

Since its founding in 1968 by my husband Eliot Coleman, Four Season Farm has sought to produce the best vegetables possible, using soil-based organic methods, on a small amount of land. When I showed up in 1991, Eliot had begun to pioneer winter vegetable production, and I was delighted to give up the landscape design business I’d run in Connecticut and grow veggies with him. Then, about 10 years ago, flowers started to creep in.

When Erin Benzakein and her family started growing flowers commercially eight years ago at Floret Flower Farm in Washington State’s Skagit Valley, perennials were an important part of the mix. After weed pressure and voles wreaked havoc on the perennials, they switched to annuals only. “We were focusing on high volume and annuals,” Benzakein said recently.

When Erin Benzakein and her family started growing flowers commercially eight years ago at Floret Flower Farm in Washington State’s Skagit Valley, perennials were an important part of the mix. After weed pressure and voles wreaked havoc on the perennials, they switched to annuals only. “We were focusing on high volume and annuals,” Benzakein said recently.

Farmer to Farmer Profile

Farmer to Farmer Profile