Promising models for reducing emissions from greenhouse growing

While working at Ferme des Quatre-Temps as an apprentice and then as farm manager, I was able to be directly involved in the development of year-round production methods. With several greenhouses sitting empty in winter, the initial idea was simple: why not make these structures profitable 12 months a year?

Being comfortable is a nice benefit of working in a minimally-heated greenhouse.

Being comfortable is a nice benefit of working in a minimally-heated greenhouse.

The project quickly took shape under the initiative of various apprentices on the farm, who were fascinated by the idea of growing vegetables in an unheated greenhouse in a northern climate like Quebec’s. With temperatures regularly reaching -22°F (-30°C) in winter months, we thought, can we really pull off this feat? Will bok choy, kale, arugula and spinach survive with only a greenhouse and floating row cover to protect them from the cold winter wind?

With few guidelines to fall back on, we set out with the simplest method possible: trial and error. Direct experience taught us most of what we now know. We lost a lot of crops in these tests and froze our hands more than once. But what I remember most of all is our amazement at the resilience of cold-hardy vegetables.

How many times have we walked into a greenhouse in the morning, thinking our frozen vegetables had died, only to return in the afternoon to find them completely thawed and healthier than ever?

One of the greenhouses (100’x 42’) that is in production during the winter.

One of the greenhouses (100’x 42’) that is in production during the winter.

Once we were convinced that it was possible to grow vegetables in the cold, we set about experimenting with all possible production factors to find the most profitable recipe. We tested crop spacings, vegetable varieties and cultivars, planting dates and so on. We meticulously took notes each season to repeat our successes and improve on what we learned from our mistakes.

In this past year, we realized that one of the most important factors we needed to work on to ensure the profitability of our winter production was greenhouse heating.

This idea came to us because of our pre-existing greenhouse installations. During the farm’s start-up phase, radiant soil heating was installed to transplant tomatoes into our multispan greenhouse in March. This choice of production calendar stemmed from a need to have early tomatoes at market to build customer loyalty.

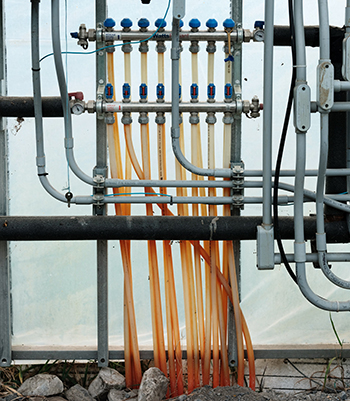

Having access to this heating system, we came up with the idea of starting it up in the autumn and using it to grow our winter vegetables from September to March. As the deeper layers of the soil are naturally maintained at around 46°F (8°C), we started our system at this same temperature. Since the heating system is buried in the soil at a depth of 18 inches, this temperature setting makes it possible to heat the top layer of soil at a relatively low cost.

After a few test seasons with this radiant heating system, we observed that crops in the soil-heated greenhouse were always the most beautiful and productive. This observation gave us an idea: should we move away from our minimal input model and slightly increase our investment in winter production with heating to increase the yields and quality of our winter crops?

The biggest obstacle to this idea of switching to minimally heated greenhouses in the winter are the air heating systems that are readily available on the market today. The easiest to install is a propane heating system. Although inexpensive to install, it is very expensive to operate in winter because of the gas cost. Its use threatens the profitability of a winter production season.

As with most small farms in Quebec, our greenhouses are all equipped with propane heating. Having this system already in place, we tested it over several seasons with a minimum heating setpoint of 37°F to 41°F (3°C to 5°C) throughout the winter. The results on our crops were even more impressive than those of soil heating.

We saw a doubling of our yields, in addition to discovering incredible working comfort. No more need to install and handle row covers on the crops, no more crop losses due to too-cold nights and no more frozen knees on the ground during harvest.

On the other hand, our heating costs were exorbitant, calling into question the economic relevance of our winter production. Faced with this challenge, we teamed up with a team of researchers from the University of Sherbrooke and the engineering firm Gobeil & Dion to find solutions to continue improving our winter production.

The micro objective we gave them was: how can we heat our greenhouses minimally (to a maximum of 41°F) in winter in an ecological way (i.e., without using fossil fuels), while also reducing our heating costs compared with using propane? Our macro objective was to demonstrate that local and sustainable production year-round is possible in a northern climate.

The University of Sherbrooke and its Faculty of Engineering proposed two innovative solutions for us to test. We decided to install them at the Ferme des Quatre-Temps in our multispan greenhouse, in order to further advance this technology. The two systems proposed were: 1) warming the air with geothermal heat and 2) a carbon dioxide heat pump.

Aerogeothermal heat

This heating system is inspired by the climate battery model. The principle behind aerogeothermal heating is simple: to capture the heat naturally present in the soil and transfer it to the air in the greenhouse for very low-cost heating.

The special feature of this system is that it uses very large, perforated ducts (24 inches in diameter) to transport the air. What’s more, unlike the traditional climate battery model, the pipes are buried outside the greenhouse under coarse gravel. These pipes are connected to a large fan located inside the greenhouse. The fan draws the air heated in the pipes and transports it into the greenhouse where it is used to heat the ambient air.

The pipes for the radiant heating system are buried in the soil 18 inches under the crops.

The pipes for the radiant heating system are buried in the soil 18 inches under the crops.

The hypothesis we are currently working with is that this system will enable the greenhouse to be heated to 41°F (5°C) in winter, with almost no other heating. This system can also be reversed in summer to dehumidify and cool the greenhouse.

We still have to test this system over several seasons before we can draw any definite conclusions. What is certain, however, is that this avenue is particularly exciting, since the system is relatively inexpensive to build (around $15,000) and involves almost no cost to operate. The only cost is the small amount of electricity the fan requires to run.

We can imagine a future in which many northern greenhouses are equipped with a heating system similar to this one. Winter production possibilities will increase tenfold, since it will be possible to minimally heat greenhouses for next to nothing.

Heat pump

The second option submitted to us for testing by the University of Sherbrooke was the idea of heating our greenhouse with a heat pump. This is a particularly energy-efficient form of electric heating. The basic principle of a heat pump is to be able to reverse the natural principle of heat transfer (hot toward cold). A heat pump, on the other hand, moves energy from cold air toward hot air, thanks in part to the use of a refrigerant. The model used on the farm captures energy from the outside air and then dissipates it into the greenhouse air as heat.

The first step in building the aerogeothermal system is to dig a large trench where the air ducts will be buried.

The first step in building the aerogeothermal system is to dig a large trench where the air ducts will be buried.

Thanks to this system, the heat pump takes 1 kWh of paid electricity and transforms it into 2 kWh worth of heat, hence its high energy efficiency. However, the big disadvantage of this heating system is that it’s less efficient when it’s cold, so a heating back-up is needed relatively often to compensate in the winter. Another drawback to the heat pump is its high installation cost: around $40,000 for a detached greenhouse (100 foot x 42 foot).

The second step in building the aerogeothermal system is to cover the pipes with coarse gravel.

The second step in building the aerogeothermal system is to cover the pipes with coarse gravel.

To install a heat pump, you need approximately 25 kW of power. Make sure your electrical panel can provide the heat pump power before installing it.

Using an electric heat pump to heat a greenhouse emits 30 tons less CO2 than heating with propane, making it an ecological option, but not a 100 percent carbon neutral solution. In fact, an individual 100 foot x 42 foot greenhouse heated with a heat pump still emits CO2, due to frequent triggering of the propane back-up when heat pump efficiency drops in cold weather. To reduce this CO2 emission even further, we’d have to replace the propane back-up heating system with an electric one.

Resistive electric heating

While working with the engineering firm Gobeil & Dion, we wanted to test the most proven and least expensive ecological heating solution for greenhouses. For this reason, we asked them to develop an electric resistive, or coil heating system, for our three individual greenhouses.

Coil heating operating principle is the same as of a household heater: a current is sent through a conductive material and the resistance of this material transforms the current into heat. Energy is then dissipated in the form of heat with1:1 energy efficiency, i.e. 1kWh of electricity generates 1kWh worth of heat.

With this system, there’s no energy loss which means that 100 percent of the energy supplied in electricity is transformed into heat. To compare, a propane furnace has 80 percent energy efficiency; 20 percent of the energy is lost and not transformed as heat. Another advantage of electric coil furnaces is their low installation cost ($11,000) compared with $40,000 for a heat pump.

To install one electric resistive furnace in an individual greenhouse (100 foot x 42 foot), you will need 50 kW of electric power, i.e., two times more than what you need for a heat pump. The first step in evaluating this option is to check whether this electrical power is available on your farm.

A greenhouse heated by an electric coil furnace emits 40 tons less CO2 than a propane heating system and it emits only 10 tons of CO2/year. The reason why this system emits less CO2 than a heat pump is because electric resistive heating doesn’t lose energy efficiency in cold weather. The propane back-up heating system is used less in this scenario.

An important caveat to bear in mind is that these ideas (heat pump and electric coil) work in a context like Quebec’s, where the installation of these systems is subsidized by the government at a rate of 75 percent in addition to the fact that we get preferential rates (5,59 ¢/kWh) on our electricity bills. Our electricity is also generated by a relatively environmentally-friendly source: hydropower.

Our hope is that these ideas will be developed in this favorable context, and then implemented elsewhere when proven. What I observe is that change in agriculture, and in many other fields, too, comes when alternatives to the status quo are demonstrated in action. With all these non-fossil fuel heating tests, we hope to bring about this change through practice.

Many obstacles remain, but through the accumulation of small actions like ours, I’m confident that we’ll be able to reach our goal of carbon-neutral greenhouses in the coming years.

Catherine Sylvestre is a professional agronomist and leader of the market garden team at la Ferme des Quatre-Temps in Hemmingford, Quebec. She develops, implements, and teaches best practices for cold season growing, specializing in crop protection and greenhouse production for northern climates. She is also the co-author of the book, “The Winter Market Gardener.”